Recent advancements in the field of bioprinting have demonstrated promising developments in creating functional human tissues. A team of researchers at Penn State has recently introduced a novel bioprinting technique that is reported to fabricate tissues at an impressive speed of ten times faster than existing methods. This research was published in Nature Communications and indicates significant advancements in the bioprinting realm.

The Importance of Bioprinting

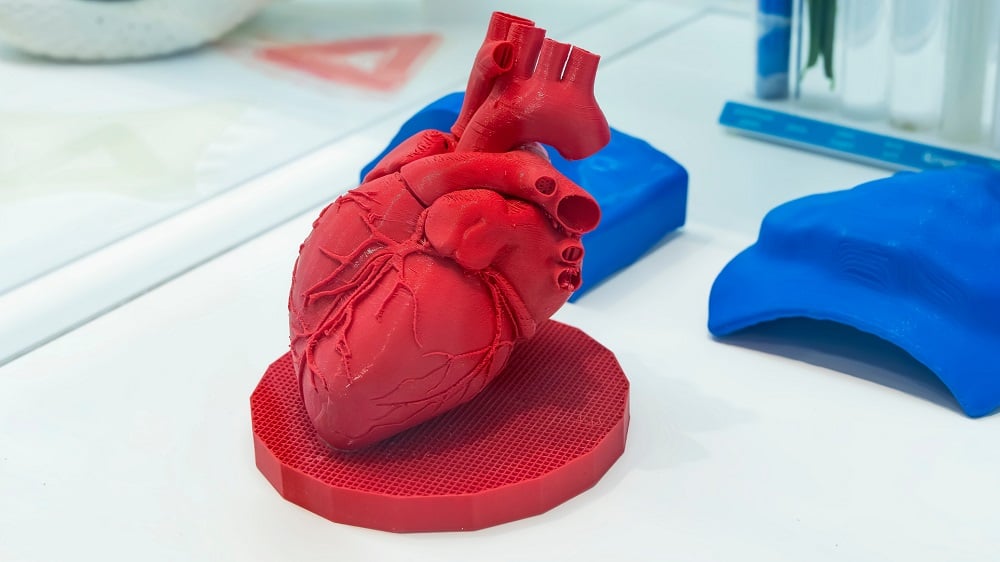

Three-dimensional (3D) printing is revolutionizing the way we conceptualize tissue engineering. The primary goal is to develop replicable human tissues for various applications, including:

- Creating organs for transplantation

- Studying disease progression

- Screening new pharmaceuticals

Despite considerable progress, the technology has faced hurdles due to challenges involving printing tissues with high cell density at scale. Existing bioprinting techniques have had limitations in precision and speed, which has hindered the creation of functional tissues that can be utilized in clinical environments.

Innovative Techniques Developed by the Penn State Team

The innovative approach introduced by the Penn State researchers involves the utilization of spheroids—clusters of living cells—as a building block for bioprinting. This method enhances the scalability and precision of tissue fabrication, allowing for the production of tissues with cell densities akin to those found in human biology.

Professor Ibrahim T. Ozbolat, a leading figure in this research, highlighted the advancements by stating,

"This technique is a significant advancement in rapid bioprinting of spheroids... at a speed much faster than existing techniques with high cell viability."

Comparison of Traditional Bioprinting and HITS-Bio Technique

| Aspect | Traditional Bioprinting | HITS-Bio Technique |

|---|---|---|

| Speed | Slow, often taking days for small structures | 10x faster |

| Cell Viability | Lower, with some cell damage | Over 90% viability |

| Control Precision | Limited, often cumbersome | High control with a 4x4 nozzle array |

Mechanism of the HITS-Bio Technique

The High-throughput Integrated Tissue Fabrication System for Bioprinting (HITS-Bio) is based on a digitally controlled nozzle array that can operate in three dimensions, allowing multiple spheroids to be manipulated concurrently. This innovative system enables rapid construction of tissue architectures while maintaining high cell viability. To demonstrate the functionality of the HITS-Bio system, the team fabricated cartilage tissue, achieving the following results:

| Feature | Details |

|---|---|

| Structure Size | 1 cm³ containing approximately 600 spheroids |

| Fabrication Time | Less than 40 minutes |

| Healing Efficacy | 91% wound healing in 3 weeks |

Clinical Implications and Future Directions

The implications of this research extend far beyond therapeutic tissues. The potential applications include:

- On-demand surgical tissue repair, as demonstrated in rat models

- Scalable production of complex organ structures

- Integration of vascular structures into bioprinted tissues, crucial for organ functionality

Future research efforts will focus on enhancing the incorporation of blood vessels within the fabricated tissues, a vital step toward realistic organ and tissue replacement.

Conclusion

The introduction of the HITS-Bio technique represents a pivotal step forward in the field of tissue engineering. As advancements in bioprinting progress, they hold the promise of transforming medical practices related to organ transplantation and regenerative medicine.

Literature Cited

[1] Myoung Hwan Kim et al. (2024). High-throughput bioprinting of spheroids for scalable tissue fabrication, Nature Communications. DOI: 10.1038/s41467-024-54504-7.

[2] Lifespan.io

Discussion